Contents, By System Component

Contents, By Bug Number

This is a list of all of the problems encountered with

the University of Iowa's PDP-8 computer.

Problems are numbered sequentially in the order of discovery.

Click on any thumbnail image to see the full-sized image.

The plastic switch handles at the left end of the row of switches are

chipped, as if they collided with something. They feel loose, and it

is probable that the plastic ears that hinge some of these switch handles

to their switches have broken. Some of the switches may also need

rebuilding, as we did with Bug 44.

|

| Loose cards

|

|---|

There are 8 card-edge connectors facing to the front on the side of the black

box holding the core memory. All but one of the circuit cards that

should be plugged into these connectors have fallen out.

|

| Right side

|

|---|

The front posts of the racks have aluminum channels holding plastic

foam weatherstrip against the cabinet skins. Whatever its purpose,

the foam in these channels has decayed.

It is brittle, and it crumbles when disturbed.

We will have to replace it with something less problematic.

The problem is similar to Bug 11, involving a foam

strip in an aluminum channel, but the dimensions are different.

|

| Cable Assembly

|

|---|

|

| Cable Connector

|

|---|

The ribbon cable assemblies that connect the left and right

half-backplanes of the machine are severely decayed.

The insulating layer on the two flex-print cable sthat make up each cable

assembly have turned to goo. We should find

an appropriate replacement material.

When the front panel with its lights and switches and the

entire computer is slid forward on its rack slides, the power supply and

rack are just barely balanced. The risk of the whole thing falling

over is significant.

- Noted Oct. 24, 2013.

- Noted Oct. 25, 2013.

Option of stabilizing leg(s) on attached table-top noted.

- Noted Oct. 28, 2013.

Note that the rack has leveling feet on the corners that have

a wider stance than the casters. These alone might suffice.

- Mitigated Jan. 23, 2014.

Leveling feet lowered to take weight off casters.

This provides only a small margin of safety when the computer

is extended from the rack!

- Solved temporarily

Feb. 05, 2014.

A wooden prop was made to support the weight of the fully

extended computer while the rack sides are removed for

access to the power supply. Replacing the table that was

formerly under the computer and had stabilizing feet would

be a better solution.

- Progress, Mar. 26, 2015.

The table originally on this PDP-8 resembles (but is smaller than)

the table on the surviving PDP-7 at the Living Computer Museum.

We got photos from them documenting the construction of that table.

- Progress, Sep. 27, 2019.

The Computer History Museum in Mountain View has a table from

a table-top PDP-8. They took extensive measurements of this table

for us. We suspect that the rack-mount table we need used most of

the same dimensions.

- Progress, Oct. 29, 2024.

Plans for reconstructing the table prepared.

|

| The latch

|

|---|

The latch that holds the half-backplanes of the computer in their

closed positions is very difficult to turn. The key is in the latch

in the photo.

The solution is to grasp the frames for the two half backplanes near the

lock with one hand and squeeze them together while turning the key

with the other hand. This releases the friction on the latch making it

easy to turn.

|

|

| Broken reader

|

|---|

|

|

| Repair in progress

|

|---|

The paper-tape reader on the Teletype was broken.

The cast ears that attached the frame of the paper tape reader

to the frame of the Teletype broke off, probably when someone used

paper-tape reader as a handle to move the Teletype. Fortunately, these

could be replaced with home-made brackets. Also, the control lever

on the paper-tape reader was broken, probably in the same accident.

- Noted Oct. 25, 2013.

- Noted Nov. 25, 2013; plastic

covers and frame casting removed from reader.

- Noted Dec. 12, 2013; frame casting

taken home for repair.

- Partially resolved Dec. 16, 2013;

home-fabricated angle brackets added to replace broken ears on frame

casting, the frame casting was re-installed on the Teletype.

- Progress, Jan. 7, 2014;

reader re-installed on frame casting. Note that reader control

lever is broken; can we glue it?

- Progress, Feb. 19, 2014;

replaced broken reader control lever with new one;

didn't finish reader reassembly.

- Solved?, Feb. 20, 2014;

reader reassembled and mechanism tested.

|

|

Before and after

|

|---|

The electrical wires at the back of the Teletype were pulled out of their

strain reliefs and needed to be redone before anyone even thinks

about plugging it in. Also, there seems to be an extra data cable.

- Noted Oct. 25, 2013.

- Noted Nov. 4, 2013;

Bug 14 and Bug 15 should

be addressed at the same time.

- Partially resolved Nov. 25, 2013;

the power cord was carefully pushed back into its strain relief

and the unknown extra cable was folded up into the case.

The data cable remains in need of proper strain relief.

- Solved, May. 1, 2014.

Repaired data cable installed with new strain relief.

Questions about extra data cable remain unresolved.

- Noted Sep. 9, 2014.

Created Bug 38; the extra cable is for a power supply.

|

|

| The old and replaced hammer

|

|---|

The rubber head on the Teletype print hammer was shot.

For many years, the standard fix among Teletype collectors has been

to replace the rubber with a piece of vinyl tubing, but recently,

a serious collector has manufactured new replacement hammer heads.

|

|

| Power supplies

|

|---|

The electrolytic capacitors in the power supplies need reforming.

- Noted Oct. 28, 2013.

- Noted Jan. 23, 2014.

Necessary tools and supplies acquired.

- Noted Feb. 10, 2014.

Decided to remove and partially disassemble PDP-8 power supply,

creating Bug 20.

- Progress, Feb. 11, 2014.

Removed PDP-8 power supply, began work reforming 10V capacitors.

- Noted Feb. 12, 2014.

10V capacitors reforming well.

- Noted Feb. 13, 2014.

10V capacitors reforming well.

- Progress, Feb. 14, 2014.

10V capacitors reformed.

- Noted Feb. 17, 2014.

Begin work on -15V capacitors.

- Noted Feb. 18, 2014.

C9 to C11 reforming well.

- Noted Feb. 19, 2014;

C9 to C11 reforming well.

- Progress, Feb. 20, 2014;

C9 to C11 reformed, begin work on C6 to C8.

- Noted Feb. 21, 2014;

C6 to C8 reforming well.

- Noted Feb. 24, 2014;

C6 to C8 reforming well.

- Noted Feb. 25, 2014;

C6 to C8 reforming well.

- Progress, Feb. 26, 2014;

C6 to C8 reformed, begin work on C1 to C4.

- Noted Feb. 27, 2014;

C1 to C4 reforming well.

- Noted Feb. 28, 2014.

C1 to C4 reforming well.

- Noted Mar. 2, 2014.

C1 to C4 reforming well.

- Noted Mar. 3, 2014.

C1 to C4 reforming well.

- Noted Mar. 4, 2014.

C1 to C4 reforming well.

- Noted Mar. 5, 2014.

C1 to C4 reforming well.

- Progress, Mar. 6, 2014.

C1 to C4 reformed, begin work on C5, C15 and C16.

- Noted Mar. 7, 2014.

C5, C15 and C16 reforming well.

- Noted Mar. 9, 2014.

C5, C15 and C16 reforming well.

- Noted Mar. 10, 2014.

C5, C15 and C16 reforming well.

- Progress, Mar. 11, 2014.

C5 reformed, C15 and C16 reforming, but one may be bad.

- Noted Mar. 12, 2014.

- Noted Mar. 13, 2014.

C16 reforming, C15 confirmed bad.

- Progress, Mar. 16, 2014.

C16 reformed, start work on capacitors in Teletype Call Control Unit.

- Noted Mar. 20, 2014.

TTY CCU caps reforming well, with replacement for C15.

- Noted Mar. 24, 2014.

TTY CCU cap reforming well, with replacement for C15.

- Partially solved, Mar. 27, 2014.

TTY CCU cap and replacement for C15 reformed!

This completes the reforming of the capacitors

in the Teletype and PDP-8 power supply.

- Noted Apr. 30, 2014.

Extract Type 779 power supply for reforming,

creating Bug 32.

- Noted Sept. 9, 2014.

Capacitors C1 to C3 reforming.

- Noted Sept. 10, 2014.

Capacitors C1 to C3 held at 25V.

- Progress, Sept. 18, 2014.

Capacitors C1 to C3 tested, not great but acceptable.

- Partially solved, Oct. 2, 2014.

Capacitors C4 to C6 tested, not great but acceptable.

This completes the reforming of the capacitors

in the Type 779 power supply.

- Noted Nov. 14, 2014.

Start work on the capacitor in the Teletype tape-reader supply.

- Progress, Dec. 1, 2014.

Change approach to the TR supply to get above 50 volts.

- Progress, Dec. 3, 2014.

Reforming voltage idling at 125V.

- Progress, Dec. 4, 2014.

Reforming voltage idling at 155V, but job only half done.

- Noted, Oct. 30, 2025.

Set up to reform high-speed reader-punch power supply,

creating Bug 79.

- Progress Nov 3, 2025

Reader-punch supply idles OK at 12.5V.

- Partially solved, Nov 17, 2025

Finished reforming Reader-punch supply.

|

| Door gasket

|

|---|

The foam gaskets that seal the vertical edges of the rear plenum

door of each cabinet need renewal.

The problem is similar to Bug 3, involving a foam

strip in an aluminum channel, but the dimensions are different. Each door

has two gaskets, one on the latch side that is easy to see, and one on the

hinge side that is most apparent only when the door is open and the hinge-side

skin of the rack is removed.

|

| Tally reader cable

|

|---|

Where is the Tally reader interface that the card-edge connector on the

reader cable connects to? And, what slot in the reader interface?

As of the identification of this bug, the cable has been plugged into the

back of the Tally reader. Mapping of the 34D Scope display interface

revealed that this backplane segment at the bottom of the ADC rack includes

the high-speed reader interface. Unfortunately, on further investigation,

it turned out that the cable, while it may have originally served this

reader, had been extensively modified and must be rebuilt.

|

| Dangling Jones plug

|

|---|

The 2-pin Jones plug on the back of the connector to the Tally paper tape

reader appears to be intended to bring power to the reader's drive motor.

Verify this, and then make the appropriate secondary cable to bring 110V power

from the power distribution panel on the ADC rack to this plug.

|

Cable repair

|

|---|

The Teletype data cable was cut between the W070 connector to the computer

and the 12-pin Jones plug at the back of the Teletype. The bad parts near the

ends of the cable were cut out and the salvaged remainder was reinstalled

with a 6-pin Jones plug at the point where the cable had been cut.

The resulting cable is shorter than the original, but with the jones plug

at the point of the cut, an extension cable can easily be added.

|

| Inappropriate plug

|

|---|

The 12-pin Jones plug in the Teletype cable was not really appropriate.

By 1970, DEC was using an 8-pin in-line Mate-n-Lok connector at this

point, but (as evidenced by the 12-pin connector here), earlier DEC users

who wanted a plug in their cables frequently used Jones plugs.

6-pin Jones plugs are still available, so we installed one.

- Noted Nov. 4, 2013, along with

Bug 8 and Bug 14.

- Noted Mar. 6, 2014.

New 6-pin Jones plugs acquired to replace 12-pin plugs.

- Noted Mar. 20, 2014.

Completed reverse engineering of cable, proposal for connector pinout.

- Progress, Mar. 27, 2014.

Old connector discarded; start installing replacement.

- Solved, May. 1, 2014.

New connector installed on cable to Teletype and W070 board.

|

| Cut power wires

|

|---|

The power distribution wiring harness between the ADC Rack and the PDP-8 rack

was cut, close to the terminal strip at the right rear corner of the rack.

The power cabling for the both racks will need careful checking.

- Noted Nov. 7, 2013.

The cut end on the ADC rack was identified.

- Noted Feb. 10, 2014.

The other side of the cut was located in the CPU cabinet

and coiled out of the way.

- Progress, Apr. 4, 2014 A bad wire

on one of the cooling fans was cut out and replaced. The plug

on the PDP-8 line cord was declared unsafe.

- Progress, Dec. 5, 2014.

We began work on the cable between the computer and ADC racks.

- Progress, Jan. 23, 2015.

Start reverse engineering the Type 834 power control panel.

- Progress, Jan. 27, 2015.

Mercury relay tested and documented.

- Progress, Jan. 30, 2015.

Unsafe rack wiring documented.

- Solved?, Jan. 30, 2015.

Wiring in PDP-8 rack fixed and tested,

creating Bug 43.

- Progress, Dec. 11, 2025.

Account for total load of all peripherals.

|

|

| Broken cover, start repair

|

|---|

|

|

| Repair completed

|

|---|

The transparent plastic insert in the Teletype cover was cracked and

entirely broken free

from its mounting. It appears that it was thermally riveted to the inside

of the cover. The whole cover was filthy, and

had a broken mounting ear. There are also cracks and broken mounting

fingers in other parts of the cover.

- Noted Nov. 25, 2013.

- Progress, Feb. 21, 2014.

New window manufactured.

- Progress, Feb. 24, 2014.

Started solvent-welding cracks and broken mounting

fingers in the ABS casing.

- Progress, Feb. 25, 2014.

Reinforced previously glued cracks with ABS splints.

- Progress, Feb. 27, 2014.

Replaced broken window-mounting studs in cover.

- Progress, Mar. 2, 2014.

Rebuilt broken left rear mounting ear in cover.

- Progress, Mar. 3, 2014.

Rebuilt mounting ear tested by mating cover with Teletype lid.

- Solved, Mar. 13, 2014.

Permanently attached new window, installed lid in Teletype cover.

|

|

| ADC Plenum door

|

|---|

The rear plenum door of the ADC rack is missing one panel (the one below the

ADC interface panel) and about 20 screws. This admits dust and degrades the

effectiveness of the rack's cooling fan. A somewhat battered replacement

panel has been located -- original DEC manufacture, formerly part of PDP-9

serial number 120.

- Noted Dec. 12, 2013.

- Partially resolved Jan. 7, 2014;

the old PDP-9 panel was

patched and installed (temporarily with the wrong kind of screws).

- Solved, Apr. 14, 2014;

missing screws replaced.

|

|

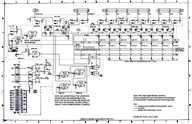

| Preliminary backplane maps

|

|---|

We need to inventory the boards in both backplanes, then remove them

and clean both the boards and the backplanes, and then re-insert the

boards where they came from. Wherever there are discrepancies between

the boards and the maintenance manuals, we will need to do more to figure

out how to put things right, suspecting boards might have been pulled and

replugged incorrectly over the years when this machine was not operational.

- Noted Jan. 23, 2014.

- Discrepancy found Mar. 24, 2014.

- Discrepancy found Apr. 29, 2014.

- Progress, Oct. 2, 2014.

Reverse engineering of the backplane begun in an effort to

resolve discrepancies.

- Progress, Jan. 22, 2015.

Exchanged three boards, eliminating all but one discrepancy.

- Progress, Jan. 27, 2015.

Resolved final discrepancy; need to document it.

|

|

| The supply out of the rack

|

|---|

|

| Opened up for capacitor access

|

|---|

To allow reforming of the capacitors in the PDP-8 power supply

(see Bug 10),

the supply needed to be removed from the rack and partially disassembled.

- created, Feb. 10, 2014.

Wiring harness almost completely removed.

- Noted Feb. 11, 2014.

Supply moved to table.

- Further damage Feb. 13, 2014.

Rivets holding back panel to supply removed.

- Further damage Feb. 14, 2014.

Back panel eased out from side panels.

- Progress, Feb. 17, 2014.

Installed swage nuts to replace pop-rivets.

- Progress, Mar. 11, 2014.

Re-connected C5 and started reconnecting C6-11.

- Progress, Mar. 16, 2014.

C6-11 and C16 reconnected.

- Progress, Mar. 27, 2014.

New C15 installed, old C17 removed.

- Progress, Apr. 4, 2014.

New C17 installed.

- Progress, May 5, 2014.

Replacement power connector work begun.

- Solved?, May 6, 2014.

Power supply reassembled and installed, creating

Bug 33.

- Reopened Oct. 29, 2014, power-OK

signal never asserted.

- Progress, Nov. 12, 2014,

Transistors Q1 and Q2 verified good.

- Solved?, Nov. 18, 2014,

Boards were in wrong slots!

|

|

| Decayed foam | New foam

|

|---|

The foam rubber pad under the typing unit was decayed and crumbled

when disturbed.

This is Teletype part number 181138, pad,

pages 25 (drawing) and 32 (parts list) in

Parts Model 32 and 33 Page Printer Set, Teletype Corp.

Bulletin 1184B, Nov. 1964, change 5.

|

| Decayed rubber

|

|---|

The rubber grommets that serve as vibration isolators were decayed and

crumbled when disturbed.

This is part number 181109, mount, vibration,

pages 25 (drawing) and 32 (parts list) in

Parts Model 32 and 33 Page Printer Set, Teletype Corp.

Bulletin 1184B, Nov. 1964, change 5.

|

| Base re-mounted

|

|---|

One teletype sub-base mounting bolt was missing.

and two more appear to have been inappropriate substitutes.

Two call control unit mounting screws were missing.

|

| The print head

|

|---|

The Teletype mechanism was dirty and the old oil and grease has congealed

to an adhesive gum. For example, the print head carriage bearings were

so thorougly gummed that they would not rotate at all before several soakings

in WD-40. Cleaning these parts requirede nearly complete disassembly

of the machine.

- Noted Feb. 11, 2014.

- Progress, Feb. 21, 2014.

Keyboard degummed.

- Progress, Apr. 4, 2014.

Printer carriage degummed.

- Progress, Apr. 14, 2014.

Equivalent for KS7470 oil noted.

- Progress, Apr. 20, 2014.

Degumming largely complete.

- Progress, , Nov. 15, 2016.

Degummed ribbon mechanism.

- Solved?, June. 22, 2017;

Platen removed, cleaned and reinstalled.

|

|

| Major subassemblies

|

|---|

Cleaning and de-gumming the Teletype required large-scale disassembly,

so we need to put it back together.

- Noted Feb. 11, 2014.

- Progress, Mar. 7, 2014.

Keyboard reassembled, but needs lubrication.

- Progress, Apr. 29, 2014.

Typing unit reassembly started.

- Progress, Apr. 30, 2014.

Reassembly continues.

- Progress, May. 12, 2014.

Typing unit reassembled.

- Progress, Nov. 11, 2014.

Broke a screw, creating Bug 39.

- Progress, Dec. 3, 2014.

Paper tape punch reattached to typing unit.

|

| Parts re-united

|

|---|

|

| Reassembled

|

|---|

- Progress, Jan. 14, 2015;

All sub-base castings reunited and mounted on pedestal.

- Progress, Jan. 29, 2015;

Rebuild keyboard contact block.

- Progress, Feb. 02, 2015;

Keyboard reassembled and mounted to base.

- Progress, Feb. 04, 2015;

Call Control Unit mounted and wired.

- Progress, Feb. 16, 2015;

powered up, creating Bug 48,

Loose spring found.

- Progress, Mar. 30, 2015;

Loose spring misidentified, keyboard fixed?

- Progress, Apr. 2, 2015;

Loose spring correctly reinstalled.

- Progress, Nov. 15, 2016.

Reassembled and lubricated ribbon mechanism.

- Progress, Mar. 28, 2016.

Note status of reassembly.

- Solved!, May 17, 2019.

Reassembly completed!

|

|

| The keyboard, before and after

|

|---|

The Teletype keyboard keys were in very bad shape. The outer grey

layer of many keys has almost shattered into multiple fragments that

are not strongly attached to the white core of each key. Zoom in on

the photo for details. Can we buy or make new keys? Consider the

keys here that were made with laser-engraved acrylic filled with contrasting

paint, then laser cut and laminated to build up the required depth.

We eventually found a source of new-old-stock keys and replaced the

worst of the bad ones.

|

|

| Tally capstan and take-up reel drive

|

|---|

The Tally 424 paper-tape reader mechanism needs to be properly lubricated.

This will require partial disassembly and reassembly of the reader.

|

|

| The capacitor and replacement

|

|---|

The Tally paper-tape reader motor uses a 3µF paper and oil capacitor.

Given the time period when this was made, it is almost certainly filled with

PCB oil and reports from others suggest that failures are not uncommon and

occasionally explosive. Therefore, it must be replaced.

|

| The motor stator

|

|---|

The power leads to the Tally paper-tape reader motor were in bad

conditon and needed replacement.

|

| Installing a rivnut

|

|---|

|

| Removing wiring

|

|---|

When the Psychology department mounted the Tally reader and magnetic tape

interface in spare spots in the ADC rack, they drilled out some of the rivnuts

DEC had installed and drilled (carelessly) some new holes. Before we

remount the Tally reader and any other peripherals in this rack, we should

replace the missing rivnuts. We will need to replace other missing parts of

this rack, and if we change the configuration of equipment in this rack,

we may need to add new rivnuts. We also need to remove the wiring and

electronics for the peripherals we no-longer have.

- Progress, Apr. 29, 2014.

Missing rivnuts replaced.

- Progress, May 5, 2014.

New doorstop for top front doors.

- Progress, Feb 14, 2018.

Remove wiring for mag-tape drive.

- Progress, Feb 21, 2018.

Remove bulk of mag-tape drive interface. Parts remain in row D of the ADC

interface.

|

The supply

|

|---|

In order to reform the capacitors in the Type 779 power supply, it

had to be extracted from the ADC rack.

- created, Apr. 30, 2014.

Extract Type 779 power supply for reforming.

- Progress, Oct. 2, 2014.

Capacitors reformed, reassembly started.

- Solved, Oct. 9, 2014.

Supply reassembled, tested and put back in the ADC rack.

|

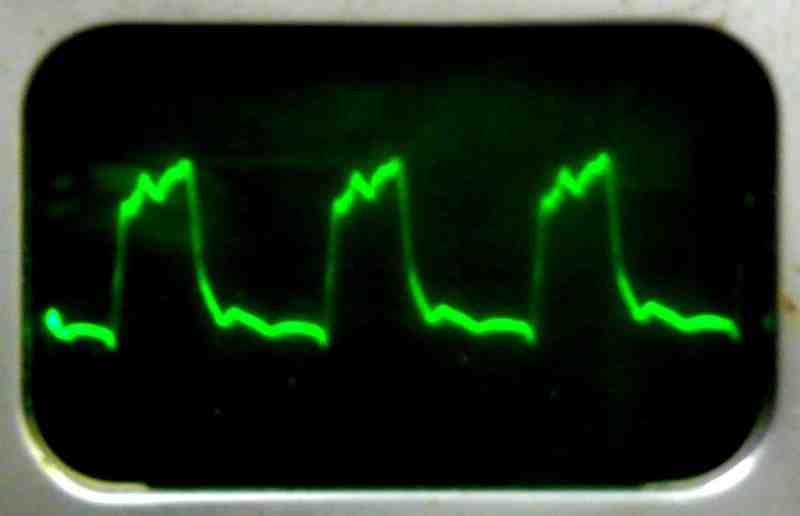

|

| Test load

| 10V at 10A 300mV

|

|---|

With the capacitors reformed and the power supply reassembled, it is time

to test it. This involves constructing a dummy load and measuring all of

the outputs under this load.

|

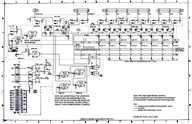

| Type 750 controller, as found |

|---|

The Tally paper tape reader interface is a subsystem of the

Type 34D Oscilloscope Display backplane.

DEC designed this interface as the Type 750C High Speed Reader, but that

interface appears to be designed for a photoelectric reader. There is

evidence of tinkering in the backplane here, so we need to thoroughly

understand what was done to make the DEC interface work with the Tally reader.

- created, June 2, 2014.

- Progress, June 13, 2014.

Cable connector reverse engineered.

- Progress, Oct. 2, 2014.

Backplane reverse engineering started.

- Reopened, June 24, 2025.

- Major progress July 1, 2025

Controller, as found, reverse engineered.

|

| Trimmer added

|

|---|

The Marginal Check power supply panel meter reads about 10% high compared

to the VOM used in power supply testing.

The Inhibit and Read/Write supplies do not work. These are regulated

supplies with outputs that only connect when both voltages are within spec.

A relay driver performs the logical and function.

- created, Aug. 13, 2014.

Created Bug 37.

- Progress, Oct. 29, 2014.

Preliminary measurements.

- Progress, Nov. 12, 2014.

Dead-end hypothesis.

- Progress, Nov. 18, 2014.

Boards were in wrong slots!

- Solved?, Dec. 16, 2014.

Outputs within spec.

|

| W982 Board

|

|---|

The Inhibit and Read/Write supplies do not work. These are regulated

supplies with outputs that only connect when both voltages are within spec.

A relay driver performs the logical and function.

|

| The Supply

|

|---|

The power supply for the Teletype mounts either on the Call Control Unit

or on in the Teletype pedestal. Our supply was missing, but we obtained a

broken one from eBay for a pittance. Unfortunately, it is broken, and it

came without a mounting bracket.

- created, Sep. 9, 2014.

Broken power supply obtained.

- Progress, Sept. 10, 2014.

Missing circuit trace rewired.

- Progress, Nov. 9, 2014.

- Progress, Nov. 11, 2014.

Mounting bracket fabricated and installed.

- Progress, Nov. 14, 2014.

Fish paper and grounding strap installed.

- Solved, Dec. 1, 2014.

Fish-paper shield installed. Now, we need to reform the

capacitor, more work on Bug 10.

Teletype part-number 182891 is a very unusual screw. Unfortunately,

the fat screw head invites overtightening. Fortunately, the huge

screw head means that this screw can be repaired.

- Created Nov. 11, 2014.

Overtightened screw breaks.

- Solved, Dec. 1, 2014.

Old screw head drilled and tapped to hold a new screw body.

The sense amplifier in backplane slot MB30 was damaged during the

backplane inventory and cleaning (see

Bug 19). The repair was essentially straightforward.

- noted, Dec. 4, 2014.

Broken pin-connector socket for sense wire on handle-side of board.

- Solved, Dec. 5, 2014.

Repaired using D-subminiature socket parts.

|

| Lugs replaced with screws

|

|---|

The cover over the Teletype keyboard was supported and aligned on 3 mounting

lugs, all of which have broken off.

|

|

| Original | Rebuilt

|

|---|

With the power supply tested and the rack wiring fixed, we can

turn on the computer. Now we must see if it works!

- noted, Feb. 04, 2015.

First power to PDP-8, some front panel lights work.

- Stalled Feb. 05, 2015.

Created Bug 44.

- Stalled Feb. 11, 2015.

Created Bug 46 and Bug 47.

- Progress, Apr. 21, 2015.

Begun functional testing from the front panel;

found some bugs.

- Progress, Apr. 22, 2015.

Created Bug 49, also note some poor switches.

- Major progress, Jul 10, 2025

Start programming!

- Progress, Jul 15, 2025

More programming.

- Progress, Jul 15, 2025

Video of front panel.

- Progress, Jul 22, 2025

Video of testing MQ register.

- work, Sep 29, 2025

First attempt to use TTY interface.

- Progress, Oct 6, 2025

TTY interface does not work.

Created Bug 77.

- Progress, Oct 9, 2025

TTY output works.

- Progress, Oct 16, 2025

TTY input works.

- Progress, Oct 30, 2025

Subroutines work.

|

|

| Switch parts during cleaning

|

|---|

After turning on the computer, we found that power was not reaching

all parts of the PDP-8 backplane. The problem turned out to lie in the

switches that allow switching each row of the backplane from the primary

power supply to the variable voltage marginal-test power supply.

Repair or replacement of these switches is in order.

- noted, Feb. 05, 2015.

Document the switches.

- Progress, Feb. 06, 2015.

Begin repairing the memory-side switches.

- Progress, Feb. 09, 2015.

Finish memory-side switches, start CPU-side.

- Progress, Feb. 09, 2015.

- Solved, Feb. 10, 2015.

All switches reassembled and power wiring tested.

|

| Cleaning the fans

|

|---|

There was considerable dust on the bottoms of the 3 fans at the bottom of

each half backplane of the PDP-8, so we removed the fan blades from their

motors, cleaned everything, and then opened the motor hubs and oiled them.

| Front panel

To deal with Bug 1 and Bug 47,

we had to disassemble the PDP-8 front panel. It will need reassembly.

|

|

| The lamps. | All lamps lit!

|

|---|

When we began testing the PDP-8

(Bug 43)

we found that many of the bulbs on the

front panel did not light, although other evidence suggested that

the bulbs ought to light.

- created, Feb. 11, 2015.

Front panel removed and opened up.

- Progress, Feb. 17, 2015.

Got replacement lamps and reverse engineered lamp circuitry.

- Progress, Feb. 23, 2015.

Replaced a total of 28 lamps, one remains inoperable, a bad transistor?

- Progress, Apr. 3, 2015.

Open up front panel to gain access to transistor in question.

- Progress, Apr. 6, 2015.

The problem was a bad circuit trace, not a bad transistor.

- Progress, Apr. 9, 2015.

Three more lamps failed during front panel reassembly.

- Solved, Apr. 13, 2015.

All lamps now light!

|

|

| First test | 11 weeks later

|

|---|

Having reassembled the Teletype, it is time to see how it works.

- created, Feb. 16, 2015;

it chatters away when it should be idling.

- Progress, Oct. 14, 2015;

Created Bug 52, adjust the Teletype.

- Progress, July 19, 2016;

Tape punch works but punches wrong data.

- Progress, July 20, 2016;

Tape punch works, punches as typed.

- Progress, Sep. 13, 2016;

Space, CR, LF, work, but types wrong letters.

- Progress, Sep. 27, 2016;

Most letters print most of the time, but stutters.

- Progress, Oct. 13, 2016;

M misprints as ←, and F, N, V and 6 misaligned.

- Progress, Dec. 1, 2016;

S occasionally misprints as ←, T and I also problematic.

- Progress, Dec. 8, 2016;

Pretty reliable, but occasional doubles and the bell rings too much.

- Progress, Mar. 7, 2017;

Very reliable, but occasional problems with V and W at high speed.

|

| Testing the R211

|

|---|

The R211 boards are double-height boards.

Each hold one bit of the memory address, program counter

and memory data registers, plus the multiplexer logic for

loading those registers.

- created, Apr. 22, 2015;

The MA register on the board in slots PC8 and PD8 seems to be stuck on.

- Progress, May 19, 2015;

Something got hot when the board was powered up.

created, Bug 51.

- Progress, May 22, 2015;

took board photos,

creating Bug 50.

- Progress, June 8, 2015;

discovered that tests on May 19 may have damaged board.

- Progress, June 24, 2015;

tests on May 19 appear to have done no harm.

- Progress, July 2, 2015;

board testing points to bad transistor.

- Progress, Sept. 30, 2015;

the problem was a bad diode.

- Problem reopened Apr. 6, 2017;

PC carry propagation problem observed,

see Bug 61.

- Progress, Apr. 20, 2017;

Bad diode found, but a different bit will not load from switches.

|

|

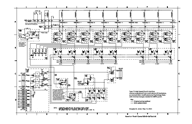

| The R211 H board.

|

|

| The R211 H reverse engineered.

|

The R211 boards are extraordinarily complex double-height boards, where

relating components on the board to the schematic diagram is not easy.

The image showing the result of the reverse engineering shows both sides

of the board, superimposed (with traces on the solder-side shaded red).

The text gives part numbers; those prefixed with equals signs (=) reference the

1965 schematic

of the R211 H;

those without reference the

1966 schematic

of the R211 J.

Markings on vias relate them to pins on the card edge connector or to the

voltages distributed on that circuit trace.

|

|

| Test fixture | Logic Probes

|

|---|

Testing boards from the PDP-8 is easier if they can be tested outside

the PDP-8 backplane. This required building a test rig and a logic test

probe.

|

| Reader stop latch

|

|---|

|

| Adjusting platen height

|

|---|

There are numerous adjustments that must be made after disassembling and

reassembling the Teletype.

- created, Oct 14, 2015;

adjusted universal lever and reader stop latch.

- Progress, July 19, 2016;

can type to punch and typing unit, results are frequently wrong.

- Progress, July 20, 2016;

"rangefinder" adjusted, punch reliably outputs what is typed.

- Progress, Sep. 27, 2016;

Correctly types most of the time, but stutters.

- Progress, Oct. 13, 2016;

Fixed stutter in function clutch (release needed adjusting).

- Progress, Nov. 15, 2016;

Fixed tension on selector magnet armature.

- Progress, Dec. 1, 2016;

Adjusted selector armature, rear carriage rail height.

- Progress, Dec. 8, 2016;

Selector armature, print hammer trip lever, distributor trip linkage.

- Progress, Feb. 2, 2017;

Adjust paper-tape punch penetration.

- Progress, June. 22, 2017;

Adjust platen height and type-drum centering.

- Progress, June. 29, 2017;

Adjust line feed drive link and up stop.

- Progress, June. 25, 2017;

Adjust platen height again.

- noted, Oct 13, 2025;

Teletype keyboard data has glitch.

- Progress! Oct 16, 2025;

Software can echo keyboard input to printer!

|

| Missing felt washers

|

|---|

The outboard end of one of the pivot shafts in the Teletype is missing several

felt washers.

- created, Feb 17, 2016;

made new felt washers, installation looks wrong.

|

| Code bar bracket

|

|---|

The bracket that serves as an alignment comb at the left end of the code bars

that serve as the main mechanical data bus in the teletype was not attached.

Floating loose on the code bars, it did not seem to be doing any harm, but

it should be attached.

|

|

| Broken | Replaced

|

|---|

The carriage return lobe plate that mounts on the left side of the carriage

was broken. This prevents the spacing mechanism from working after a carriage

return because without it, the return lever stays latched, disengaging the

spacing pawls.

Most of the control-character actuating levers was not engaged properly

with the corresponding linkages, and the corresponding function levers were not

properly engaged with their function pawls.

- created, Aug. 12, 2016;

discovered the problem.

- Progress, Sep. 8, 2016;

CR function lever now decodes, but no actuation.

- Progress, Sep. 13, 2016;

CR seems to work correctly.

- Progress, Nov. 15, 2016;

BEL and ENQ seem to work correctly, but testing fails.

During reassembly of the Teletype, the automatic codebar was inserted in the

wrong slot in the codebar assembly, causing the function bell to ring with

every character typed.

After enough of the Teletype was repaired that the typing mechanism began

working reasonably reliably, there were misprints that focused on incorrect

values of data bit 4.

- First evidence Oct. 13, 2016;

Looking back through the logs, the evicence of this problem

was first recognized and connected to bit 4.

- created, Mar. 7, 2016;

Bit 4 only converted from 0 to 1 after a 1,

and the problem is in the receiver.

- Diagnosis Mar. 23, 2016;

The selector armature is being locked prematurely in the on position.

- Solved, Mar. 28, 2016;

A small rangefinder change fixes it!

The rubber of the teletype platen is very hard, limiting the print quality.

Is there some way to recondition it?

The back panel of the teletype stand is missing.

Can we manufacture a replica of the original?

When you increment the PC, carry does not propagate from PC bit 2 to bit 1.

This is most obvious when you hit RUN with the memory disabled so all fetches

get opcode zero (AND). The PC lights up as

00X XXX XXX XXX, where bulbs marked X are on

at half intensity because they are flickering between 0 and 1.

- Problem diagnosed Apr. 6, 2017;

Moving boards pins the problem on an R211 board,

reopening Bug 49.

- Progress, Apr. 20, 2017;

Bad diode found, but a different bit will not load from switches.

|

|

| The screwdriver

| Adjusting LF drive link

|

|---|

We broke the linefeed mechanism while adjusting the platen height.

- created, June 22, 2017;

We left a screwdriver in the left platen height

pry point when we hit LF.

- Solved, June 29, 2017;

Adjusting the line feed drive link and up stop compensated for

the bending or stretching caused by our error.

|

| The problem spring

|

|---|

The paper-tape reader only runs if the clutch-trip magnet's armature at the

rear of the Teletype is held down manually. This is evidence that there's

something wrong in the wiring of the reader-run circuit.

- created, Mar. 7, 2017;

need to hold down clutch-trip armature discovered.

- Progress, July 6, 2017;

documents identified that show this should not be needed.

- Solved, July 11, 2017;

one contact spring in the reader was improperly reassembled.

|

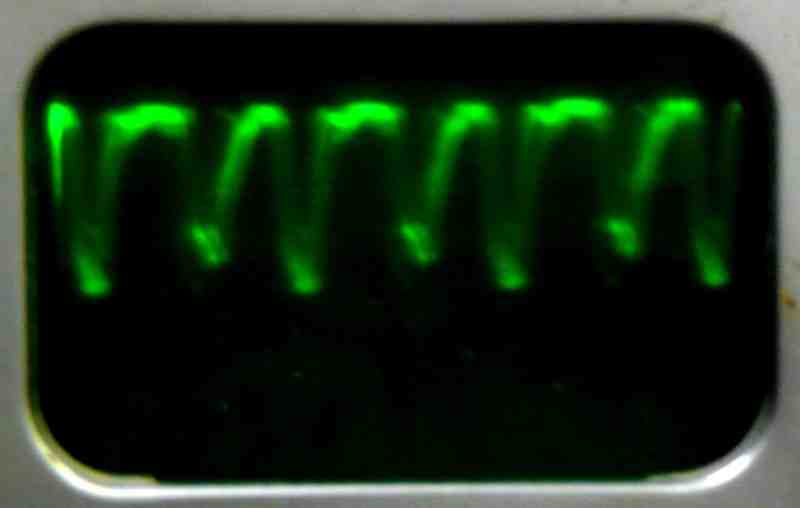

|

| Inhibit and R/W select currents

|

|---|

Memory does not work.

- Problem observed in passing Apr. 6, 2017;

memory does not work.

- Problem observed again Nov. 17, 2017;

can get data to MB register, but it reads back as zero.

- no progress Feb. 12, 2018;

speculate that a W034 cable is missing.

- small progress Feb. 21, 2018;

found the memory current limiters.

- small progress Apr. 4, 2018;

added test points to simplify current probe.

- Progress? Apr. 11, 2018;

preliminary current probe results.

- small progress Apr. 18, 2018;

useful current probe results.

- small progress Apr. 25, 2018;

check quality of power supply regulation.

- Progress? May 2, 2018;

swapping regulators has no effect.

- Progress? Sept. 13, 2018

Memory Strobe and Inhibit signals seem wrong.

- Progress? Sept. 27, 2018

Study B360 board that generates memory stribe.

- Progress? Nov. 8, 2018

Data tracked from the switch register to the Inhibit drivers.

- Progress? Dec. 6, 2018

Strobe pulse may be shorted to ground by a sense amplifier.

- Progress, Mar 19, 2019

Reverse engineer G007 sense amplifier board.

- Progress? May 17, 2019

Replace open diode in G007 sense amplifier.

- verified status unchanged, Jan 31, 2023

- found bug? Oct 9, 2024

Clock debugging.

- Progress, Oct 21, 2024

R603 reverse engineer and repair.

- Progress, Oct 28, 2024

Clock debugging.

- Progress! Oct 30, 2024

All memory timing waveforms verified to be correct.

- Progress! Nov 4, 2024

Memory current settings measured, close to correct.

- Progress, Nov 13, 2024

Memory current and voltage settings set by the book.

- Progress! Apr 14, 2025

Memory starts to work!

- Progress! May 5, 2025

Sense amplifier outputs mostly good.

- Progress? May 30, 2025

Repair G208 inhibit driver.

- Workaround found, Jul 10, 2025

Work around problem, not repair it.

- noted, Jul 22, 2025

|

|

We found that we needed to watch signals on the wire-wrapped backplane, so

we built logic probes.

|

| Test fixture

|

|---|

We found that we could only achieve marginally acceptable static balance on

the G007 sense amplifier in slot MB27.

- Identify problem, Nov 20, 2024

- Results of bug, Apr 14, 2025

Cannot read bit 5 of memory!

- Progress, May 5, 2025

Sense amp seems to work, but no ones to read.

- Progress, May 8, 2025

Rule out a broken inhibit winding.

- Progress, Jun 5, 2025

Prove that the sense amplifier is bad.

- Progress, Jun 10, 2025

Diagnose G007 sense amplifier.

- Progress, Jul 3, 2025

Compare good and bad G007 boards.

- Progress, Jul 8, 2025

Balance and compare all G007's.

- Workaround found, Jul 10, 2025

- Progress, Oct 20, 2025

Replace Q2 on weak amplifier.

- Progress, Oct 23, 2025

Redo faulty measurements.

|

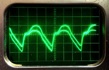

| MA11 and its inverse? |

|---|

We found noise on one of the memory address line MA11(0) with an amplitude

exceeding the signal amplitude. We will have to check all the memory address

lines.

- Identify problem, Dec 9, 2024

- Progress, Dec 11, 2024

Identify G209s as noise source.

- Progress, Dec 16, 2024

Repair diodes on G209 from slot MD12.

- Progress, Feb 13, 2025

Repair diodes on second G209, others seem good.

- Solved?, Apr 7, 2025

Test result of reapir.

- Solved?, Apr 14, 2025

Memory starts to work!

We managed to melt the wires in the ground clips of our scope probe by

shorting the +10 supply to ground through the scope. We also used the

technology we used to solve this problem to make push-on backplane

shorting jumpers.

- Create problem, Feb 13, 2025

We melted the wires.

- Solved, Feb 20, 2025

We made better ground clips and several shorting jumpers.

- continued, Oct 20, 2025

We made more shorting jumpers.

The PDP-8 documentation says it has an interface for an 8-bit BRPE paper-tape

punch. This was evidently modified by the psychology department to support a

different punch, which we do not have.

- Create problem, June 4, 2019

We got 2 6-bit BRPE punches.

creating Bug 71.

- Progress, Feb 17, 2025

Start careful disassembly.

- Progress, Mar 13, 2025

Extract linkages from one.

- Progress, Mar 20, 2025

Reverse engineer punch block,

creating Bug 70.

- Progress, Mar 31, 2025

Assemble BRPE linkages.

- Progress, Apr 3, 2025

Reassemble widened BRPE.

- Progress, Apr 7, 2025

More reassembly.

- Progress, Apr 10, 2025

Power up and feed tape!

We need an 8-bit punch block for our BRPE punch. All we have is 6-bit blocks.

Our BRPE punch came with no data cable and no power cable, just connectors

for the cable in back.

- Create problem, June 4, 2019

We noted missing BRPE punch connectors.

- Progress, Apr 7, 2025

Make a power cord, test the motor.

- Progress, Apr 17, 2025

Reverse engineer BRPE wiring.

- Progress, Apr 21, 2025

Start reverse engineering BRPE controller,

creating Bug 72.

- Progress, May 21, 2025

Cable design completed!

We have a little documentation for the oscilloscope output option that is

part of the

multi-device-controller backplane

at the bottom of the

analog to digital converter rack, but none

of this covers more than cursory details of the Type 75 high-speed

paper-tape-punch controller. There is evidence of modification to this

controller, so we will have to bite the bullet and try to do a complete job

of reverse engineering, first determining how it worked after the Psychology

department modified it to work with their Tally paper-tape punch, and then

determining how to make it work with the BRPE punch it originally supported.

- Create problem, Apr 21, 2025

Start reverse engineering controller.

- Progress, May 1, 2025

BRPE punch strobe signal conditioning.

- Progress, May 12, 2025

Trace the controller wiring.

- Solved? May 21, 2025

Reverse engineered,

creating Bug 73.

- Progress, May 28, 2025

Begin testing punch-strobe receiver.

- Solved, May 28, 2025

Finish testing W501 punch-strobe receiver.

In attempting to figure out how to undo the changes made by Psychology to the

Type 75 High Speed Punch controller, we found that both of our

W501 Schmitt Trigger boards are bad, one modified, one with a bad transistor.

We have found and replaced many bad diodes in resolving earlier bugs.

Notably, in

bug 49,

bug 61,

bug 61

and

bug 61.

This convinced us to set out on a systematic scan of all diodes on as-yet

checked boards in the CPU and peripherals.

- Start work, Jul 18, 2025

Row PA finished.

- Progress Jul 22, 2025

Row PB started, spare boards started.

- Progress Sep 18, 2025

Finished CPU and TTY interface.

- Progress Sep 29, 2025

Rows A and B on multifuction I/O backplane started.

- Progress Oct 6, 2025

Rows A and B on multifuction I/O backplane finished.

- Progress Oct 9, 2025

Found bad W040A board in row C, creating

Bug 78.

- Progress Oct 30, 2025

Row C on multifuction I/O backplane finished.

- Progress Nov 17, 2025

Scanned all R210 boards in CPU.

Someone has mined parts from the machine for use elsewhere.

- Create problem Sep 18, 2025

W050 board in MF25 missing 3 2N527 transistors.

- Solved! Oct 6, 2025

Replaced transistors.

The Teletype should be silent when the local-off-line switch is in the off

position, but instead, it makes a loud buzzing noise.

Attempting to send data to the Teletype, the most we get is one clunk from

the mechanism.

On finding a bad diode on a W040A board, we could not find a schematic

for the W040A, and it obviously differs from the well documented W040B,

so we had to reverse engineer the board to find out the role of that diode

in order to infer its specifications to find an appropriate replacement.

- Created Oct 9, 2025

Bad W040A board in multifuction I/O backplane row C.

- Solved! Oct 16, 2025;

Reverse engineering completed, board repaired.

The home-made power supply for the high-speed paper tape reader and punch

came with a range of poorly done wiring. This needs to be redone, and in

some cases, rethought.

- Created Oct 30, 2025

Old wiring from supply to backplane removed.

- Progress Nov 3, 2025

Internal supply wiring spiral wrapped.

- Progress Nov 17, 2025

Reverse engineered supply, planned changes.

- Progress, Dec. 11, 2025

It is safe to wire this supply to 120V rack wiring.